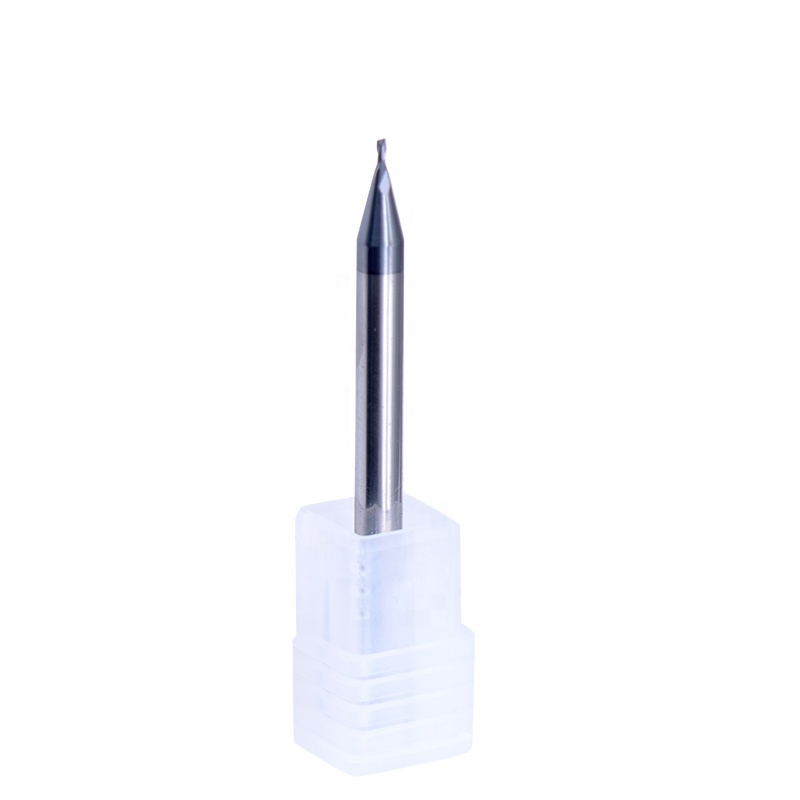

Micro Tungsten Carbide Square End Mill

Mawonekedwe

1. M'mimba mwake yaying'ono: Zigayo zazing'ono nthawi zambiri zimakhala ndi m'mimba mwake kuyambira 0.1mm mpaka 6mm, zomwe zimalola mabala olondola komanso ovuta m'mipata yothina. Izi zimathandiza kuti makina a tsatanetsatane wabwino ndi mawonekedwe ang'onoang'ono ndi olondola kwambiri.

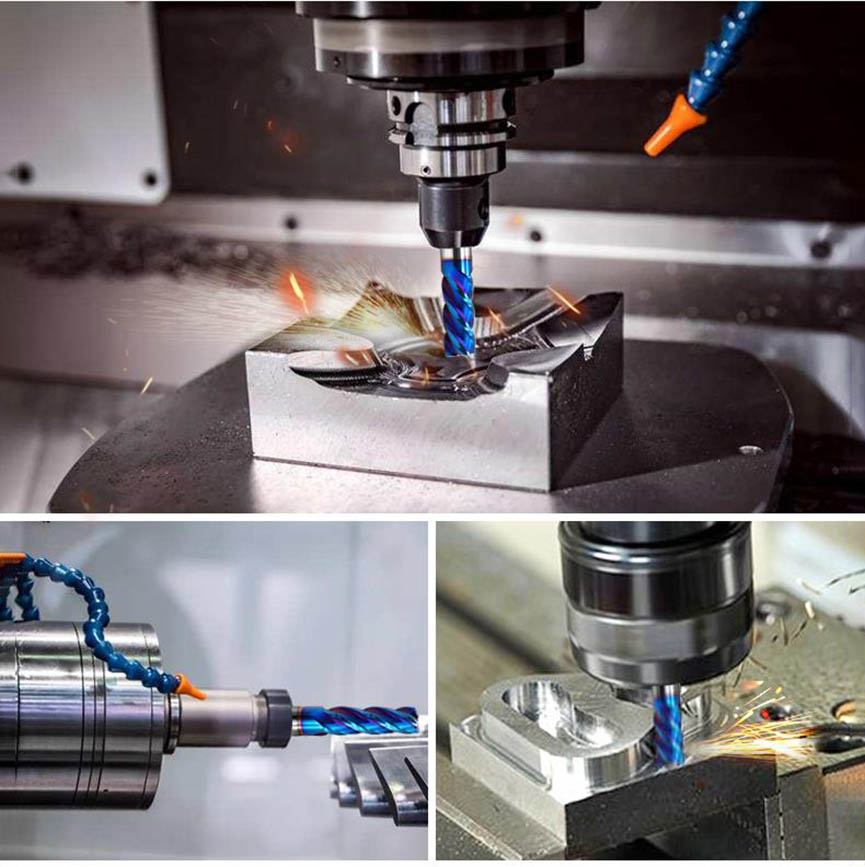

2. Kuuma kwakukulu: Tungsten carbide imadziwika chifukwa cha kuuma kwake kwakukulu, komwe kumatsimikizira kulimba kwa mphero ya micro end ndi kukana kuvala. Izi zimawapangitsa kukhala oyenera kupanga zida zolimba monga zitsulo zosapanga dzimbiri, zitsulo zolimba zolimba, ndi ma alloys amlengalenga.

3. Mphepete zakuthwa zakuthwa: Mphero zazing'ono zazing'ono zimapangidwa ndi m'mphepete lakuthwa kuti zitsimikizire mabala oyera komanso kuchepetsa chiopsezo cha kuwonongeka kwa workpiece kapena burrs. Izi ndizofunikira kwambiri pamapulogalamu omwe amafunikira kumaliza kwapamwamba komanso kulondola kwazithunzi.

4. Kusamutsidwa kwa chip moyenera: Mapangidwe a chitoliro a mphero zazing'ono amakongoletsedwa bwino kuti chip chisamuke, kuteteza chip kuchulukira ndikuwonetsetsa kuti ntchito zikuyenda bwino. Kutulutsa bwino kwa chip kumathandizira kuti zida ziziyenda bwino komanso kuchepetsa mwayi wosweka kwa zida.

5. Kuchepetsa mphamvu zodulira: Mphero zazing'ono zazing'ono zimapangidwa kuti zichepetse mphamvu zodulira, zomwe ndizofunikira makamaka pogwira ntchito ndi zinthu zosalimba kapena zoonda. Zida zochepetsera zimathandizira kupewa kupotoza kwa workpiece ndikuchepetsa mwayi wovala kapena kusweka kwa zida.

6. Zosankha zokutira: Makina omaliza a tungsten carbide amatha kupezeka ndi zokutira zosiyanasiyana, monga TiAlN, TiSiN, kapena carbon-like carbon (DLC). Zopaka zimawonjezera magwiridwe antchito a chipangizocho pochepetsa kugundana, kuwongolera kukana kuvala, komanso kutulutsa kutentha.

7. Zosankha zingapo za zitoliro: Mphero zazing'ono zimatha kukhala ndi zitoliro 2, 3, kapena 4. Kuchuluka kwa zitoliro kumakhudza kuchotsedwa kwa chip ndi kukhazikika kwa chida panthawi yodula. Kusankha kamangidwe ka chitoliro koyenera kumadalira kagwiritsidwe ntchito kake ndi zinthu zomwe zikupangidwa.

8. Zosankha za shank: Miyendo ya Micro end mphero imatha kuperekedwa ndi mitundu yosiyanasiyana ya shank, kuphatikiza ziboda zowongoka ndi ma tapered. Kusankhidwa kwa mtundu wa shank kumadalira chogwiritsira ntchito makina ndi zofunikira zenizeni za makina opangira makina.

9. Kugwiritsa ntchito zinthu zosiyanasiyana: Mphero za Micro tungsten carbide ndizoyenera kugwiritsa ntchito zosiyanasiyana, kuphatikiza makina ang'onoang'ono, engraving, contouring, ndi kubowola. Atha kugwiritsidwa ntchito m'mafakitale monga zamagetsi, zamankhwala, zakuthambo, ndiukadaulo wolondola.

10. Zosintha mwamakonda: Opanga nthawi zambiri amapereka ntchito zosinthira mphero yaying'ono, zomwe zimalola makasitomala kufotokoza m'mimba mwake, kutalika kwa chitoliro, kutalika konse, zokutira, ndi magawo ena kuti akwaniritse zosowa zawo zamakina.

tsatanetsatane wamtundu wa tungsten carbide square end mill

fakitale

| 2 Flutes Micro End Mill | ||||

| Kanthu | Chitoliro Diameter (d) | Utali wa Chitoliro (I) | Shank Diameter (D) | Utali wonse(L) |

| 0.2 * 0.4 * 4 * 50 | 0.2 | 0.4 | 4 | 50 |

| 0.3 * 0.6 * 4 * 50 | 0.3 | 0.6 | 4 | 50 |

| 0.4 * 0.8 * 4 * 50 | 0.4 | 0.8 | 4 | 50 |

| 0.5*1*4*50 | 0.5 | 1 | 4 | 50 |

| 0.6 * 1.2 * 4 * 50 | 0.6 | 1.2 | 4 | 50 |

| 0.7 * 1.4 * 4 * 50 | 0.7 | 1.4 | 4 | 50 |

| 0.8*1.6*4*50 | 0.8 | 1.6 | 4 | 50 |

| 0.9*1.8*4*50 | 0.9 | 1.8 | 4 | 50 |