Morse Taper Shank HSS End Mills

Mawonekedwe

1. Morse Taper Shank: Mphero yomalizira imakhala ndi shank yomwe idapangidwa kuti igwirizane ndi spindle ya Morse Taper. Dongosolo la Morse Taper limalola kuyika kotetezeka komanso kolondola kwa mphero pamakina ophera.

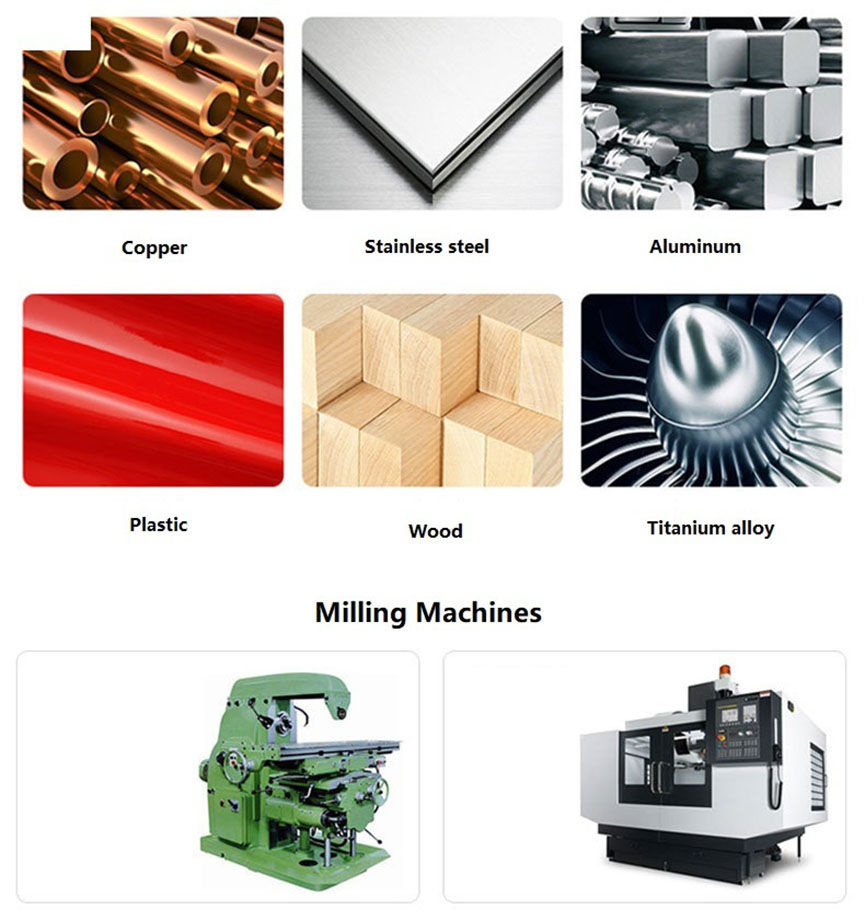

2. High-Speed Steel (HSS): HSS ndi mtundu wazitsulo zachitsulo zomwe zimagwiritsidwa ntchito podula zida. Makina omaliza a HSS amadziwika chifukwa cha kulimba kwawo, kukana kutentha, komanso kupirira kuthamanga kwambiri. HSS mapeto mphero ndi oyenera osiyanasiyana zipangizo, kuphatikizapo carbon zitsulo, aloyi zitsulo, zitsulo zosapanga dzimbiri, ndi zitsulo non-ferrous.

3. Zitoliro: Chigayo chomaliza chimakhala ndi zitoliro zingapo m'litali mwake. Zitoliro ndi ma helical kapena owongoka grooves pamwamba pa mphero yomaliza. Zitoliro zimathandizira kuchotsa chip ndikupereka m'mphepete mwa kuchotsa zinthu. Kuchuluka kwa zitoliro kumatha kusiyanasiyana kutengera momwe ntchito ikugwiritsidwira ntchito, ndipo zosankha wamba zimakhala 2, 4, kapena 6 zitoliro.

4. Cutting Edge Geometry: Makina omaliza a HSS amabwera mumitundu yosiyanasiyana, monga ma square end, mphuno ya mpira, utali wa ngodya, kapena chamfer. Jiometry iliyonse ndiyoyenera kuchita mphero inayake komanso kumaliza komwe kumafunikira.

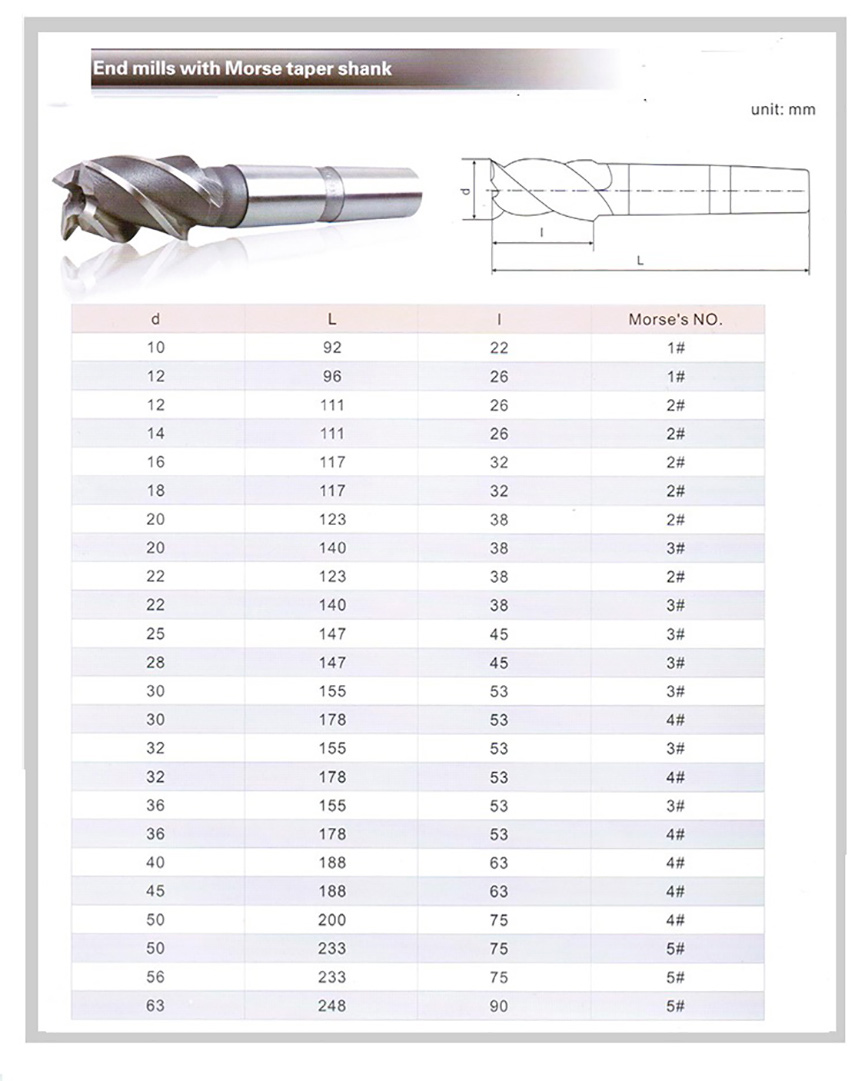

5. Utali Wonse ndi Utali wa Chitoliro: Utali wonse umatanthawuza utali wonse wa mphero yomaliza, kuchokera kunsonga kwa mphepete mpaka kumapeto kwa shank. Kutalika kwa chitoliro kumatanthauza kutalika kwa gawo lodulidwa kapena zitoliro. Utali wosiyanasiyana ulipo kuti ugwirizane ndi kuya kosiyanasiyana kwa mphero ndi zofunikira zovomerezeka.

6. Zosankha zokutira: Makina omaliza a HSS amathanso kubwera ndi njira zosiyanasiyana zokutira monga TiN, TiCN, kapena TiAlN. Zovala izi zimapereka kukana kovala bwino, kuwonjezereka kwa moyo wa zida, ndikuchita bwino pakugwiritsa ntchito kuthamanga kwambiri kapena kutentha kwambiri.

7. Kukula Kwachidule: Mapiritsi a Morse Taper shank HSS amapezeka mumiyeso yofanana yomwe imagwirizana ndi dzina la Morse Taper (MT1, MT2, MT3, etc.). Makulidwe awa amatsimikizira kukwanira koyenera komanso kugwirizana ndi makina amphero ndi ma spindles.

fakitale

Morse taper shank HSS end mphero zambiri

Ubwino wake

1. Kukwera Kotetezedwa ndi Kolondola: The Morse Taper shank imapereka malo otetezeka komanso olondola mu spindle, kuchepetsa kuthamanga ndi kuonetsetsa kudula kolondola. Izi zimathandiza kusunga kulondola kosasinthasintha komanso kutsirizika kwapamwamba pazigawo zamakina.

2. Kusinthasintha: Morse Taper shank HSS mapeto mphero akupezeka osiyanasiyana makulidwe ndi geometries, kuwapanga kukhala oyenera ntchito zosiyanasiyana mphero ndi zinthu zakuthupi. Kusinthasintha kumeneku kumapangitsa kuti pakhale ntchito zambirimbiri popanda kufunikira kokhazikitsa zida zingapo.

3. Kukhalitsa ndi Kukana Kutentha: HSS mapeto mphero amadziwika chifukwa cha kulimba kwawo ndi kukana kutentha. Amatha kupirira kuthamanga kwambiri ndikusunga ntchito yawo yodula ngakhale pansi pa kutentha kwakukulu komwe kumapangidwa panthawi yopanga makina. Kukhazikika uku kumasulira kukhala moyo wautali wa zida, kuchepetsa kuchuluka kwa zida m'malo ndi nthawi yopumira pamakina.

4. Zotsika mtengo: Makina omaliza a HSS nthawi zambiri amakhala otsika mtengo poyerekeza ndi zida zina zogwira ntchito kwambiri, monga carbide. HSS mapeto mphero amapereka bwino bwino pakati pa ntchito ndi mtengo, kuwapanga iwo kusankha koyenera machining otsika voliyumu, zipangizo zovuta, kapena ntchito ndi zofunika zochepa okhwima.

5. Kugwirizana: Mphero za Morse Taper shank HSS zidapangidwa kuti zizigwirizana ndi masipiko a Morse Taper omwe amapezeka m'makina ophera. Kugwirizana kumeneku kumathandizira kukhazikitsa zida, kumachepetsa kufunika kwa ma adapter owonjezera, ndikulola kusinthasintha kosavuta pakati pa zida zosiyanasiyana.

6. Kukonzanso Kutha: Mphero zotsiriza za HSS zimatha kuwongoleredwa mosavuta, kukulitsa moyo wawo wothandiza ndikuchepetsa mtengo wa zida pakapita nthawi. Ndi kukonza bwino ndi kunola, mphero yomaliza ya HSS imatha kupereka magwiridwe antchito komanso phindu pamakina angapo opanga makina.

7. Wide Material Compatibility: HSS mapeto mphero akhoza mogwira makina osiyanasiyana zipangizo, kuphatikizapo carbon zitsulo, aloyi zitsulo, zitsulo zosapanga dzimbiri, chitsulo chosapanga dzimbiri, zitsulo zopanda chitsulo, ndi mapulasitiki. Kusinthasintha kumeneku kumawapangitsa kukhala oyenera m'mafakitale ndi ntchito zosiyanasiyana.