Preminium Quality Tungsten Carbide Square End Mill ya Super Hard Metal

Mawonekedwe

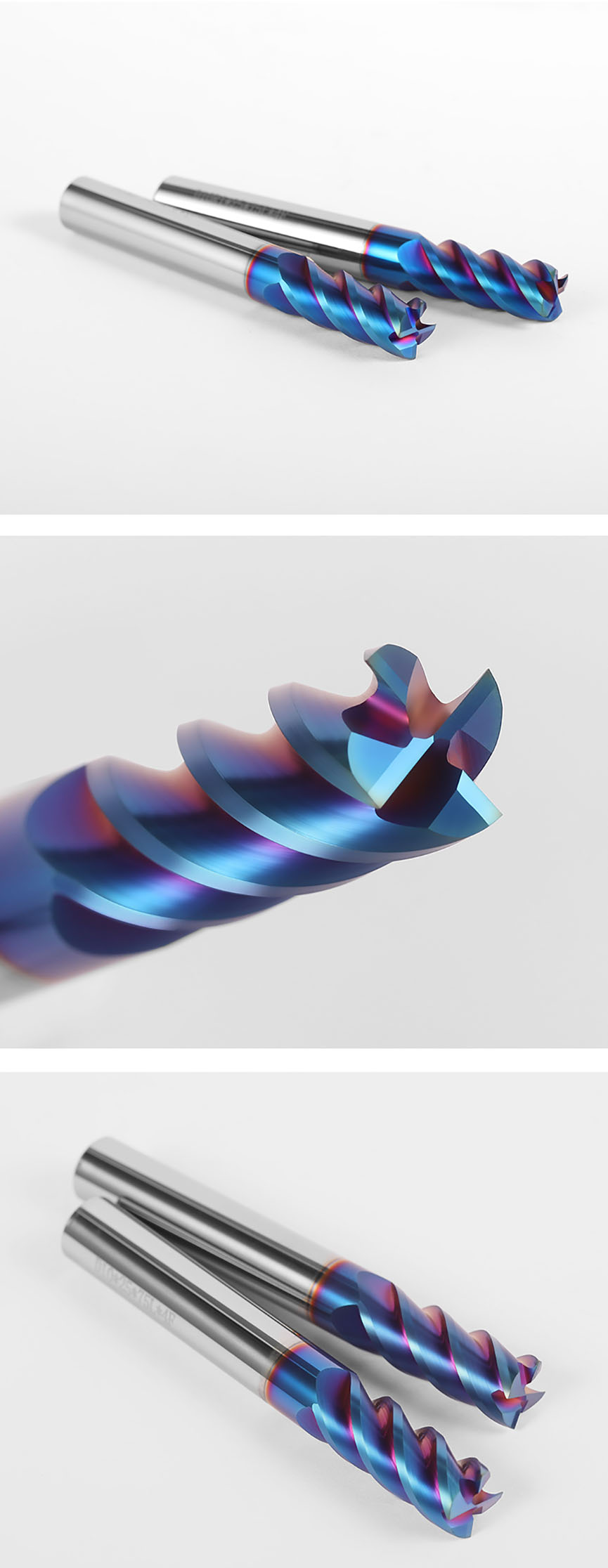

1. Kulimbitsa kulimba ndi kulimba: Zida za tungsten carbide zomwe zimagwiritsidwa ntchito kumapeto kwa mphero zimapereka kuuma kwambiri komanso kulimba, zomwe zimalola kuti zithe kupirira ntchito zamakina othamanga kwambiri komanso moyo wautali wa zida.

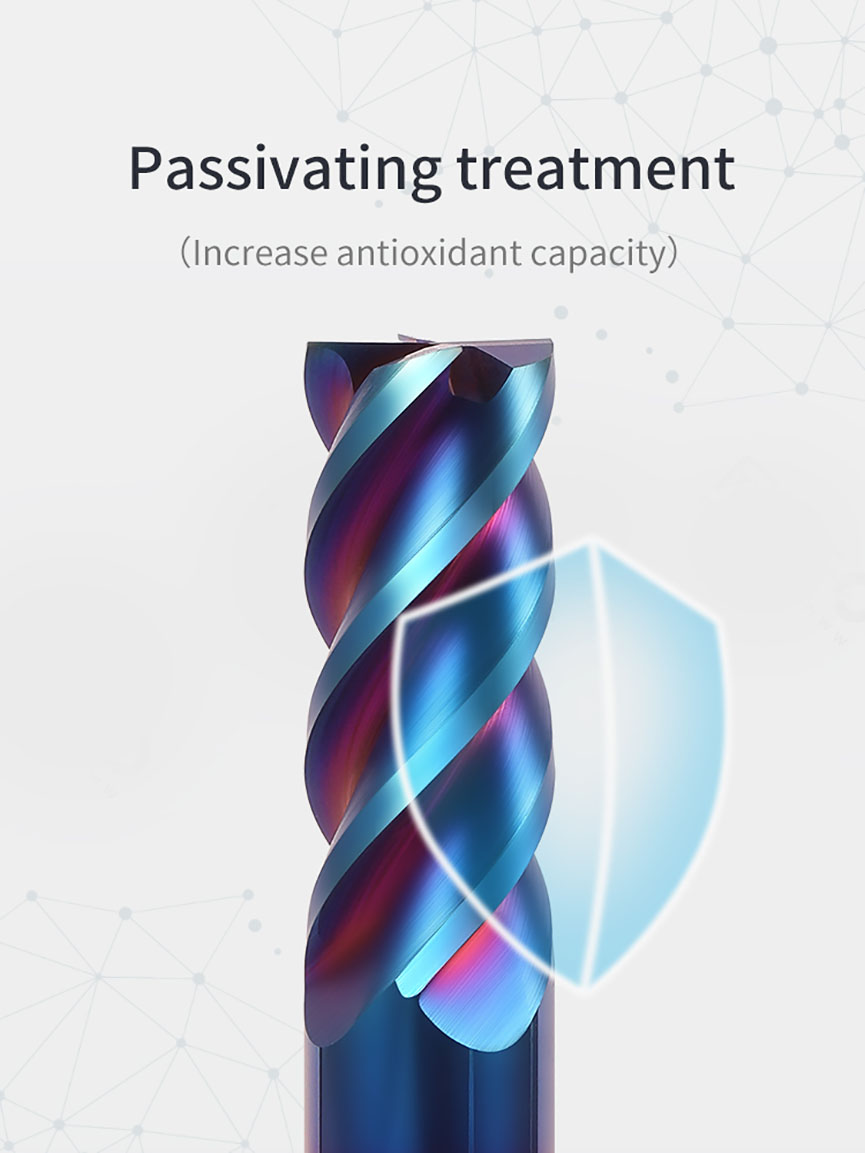

2. Chophimba cha buluu cha Nano: Chophimba cha buluu cha nano ndi filimu yopyapyala, yosalala yomwe imayikidwa pamwamba pa mphero pogwiritsa ntchito njira zamakono zokutira. Kupaka uku kumapangitsa kuti chidachi chizigwira ntchito pochepetsa kukangana ndi kutentha panthawi yodula, kukonza kutuluka kwa chip, komanso kukana kuvala ndi dzimbiri.

3. Kuwonjezeka kwachangu kudula: Chophimba cha buluu cha nano chimachepetsa kukangana pakati pa mphero yotsiriza ndi workpiece, kulola kuthamanga kwapamwamba kwambiri. Izi zimapangitsa kuti pakhale zokolola komanso zogwira ntchito bwino pamakina.

4. Kutentha kwapamwamba kwambiri: Chophimba cha buluu cha nano chimapangitsa kuti mpheroyo isamatenthedwe ndi kutentha, zomwe zimathandiza kuti zisawonongeke kutentha komwe kumapangidwa panthawi yodula. Izi zimachepetsa kupunduka kwa chida ndikutalikitsa moyo wa chida.

5. Kukana kuvala kwabwino kwambiri: Chophimba cha buluu cha nano chimapereka kukana kwapadera, kuchepetsa mavalidwe a chida ndikutalikitsa moyo wake wautumiki. Izi zimapangitsa kuti pakhale kudulidwa kosasinthasintha komanso kuchepetsa nthawi yochepetsera kusintha kwa zida.

6. Kupititsa patsogolo kutulutsa kwa chip: Kutsekemera kwa nano buluu kumapangitsa kuti chip chisamuke bwino, kuteteza chip build-up ndi kuchepetsa chiopsezo cha kuwonongeka kwa zida kapena kuwonongeka.

7. Kudula kolondola komanso kolondola: Kuphatikizika kwa zinthu zapamwamba kwambiri za tungsten carbide ndi zokutira za buluu za nano zimalola kudulidwa kolondola komanso kolondola, zomwe zimapangitsa kuti pakhale zoyera komanso zosalala pamapangidwe ogwirira ntchito.

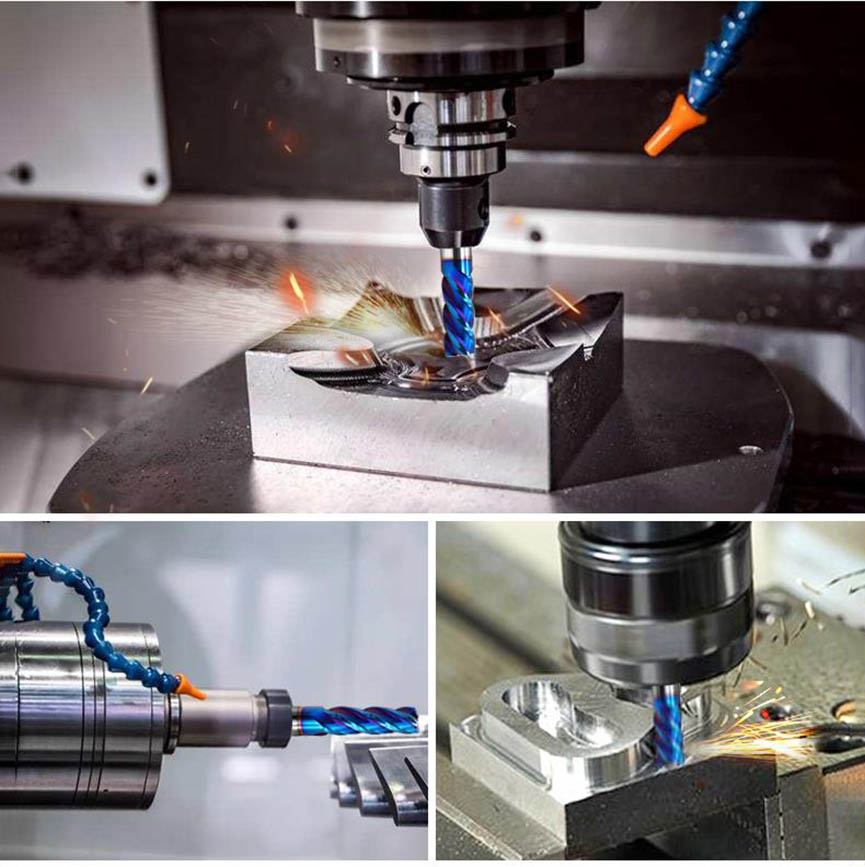

8. Kusinthasintha: Ma tungsten carbide square end mphero okhala ndi nano buluu wokutira angagwiritsidwe ntchito pa ntchito zosiyanasiyana za mphero, kuphatikizapo roughing, kumaliza, contouring, ndi mbiri mu zipangizo zosiyanasiyana monga chitsulo, zitsulo zosapanga dzimbiri, aluminiyamu, ndi zina.

tsatanetsatane wamtundu wa tungsten carbide square end mill

Chithunzi chatsatanetsatane chazinthu

Ubwino wake

1. Moyo wa zida zowonjezera: Kuphatikiza kwa tungsten carbide yapamwamba kwambiri ndi zokutira za buluu za nano kumawonjezera kwambiri moyo wa zida za mphero poyerekeza ndi zosindikizidwa zosasindikizidwa. Izi zimabweretsa kutsika kwa mtengo wa zida komanso zokolola zabwino

2. Kupititsa patsogolo kuthamanga kwachangu: Chophimba cha buluu cha nano chimachepetsa kukangana ndi kutentha kwa kutentha panthawi yodula, zomwe zimapangitsa kuti azithamanga kwambiri. Izi zimathandizira kukulitsa luso la makina ndikuchepetsa nthawi yozungulira.

3. Kuwonjezeka kwa kukana kuvala: Chophimba cha buluu cha nano chimapangitsa kuti chigayo chisawonongeke, chimapereka chitetezo ku abrasion ndi kukulitsa moyo wa chida. Izi zikutanthauza kuti zida zimasintha pafupipafupi komanso kuchepetsa nthawi yopumira.

4. Kutsirizira kwapamwamba pamwamba: Chophimba cha buluu cha nano chimachepetsa m'mphepete mwake ndikuchepetsa mphamvu zodulira, zomwe zimapangitsa kuti pakhale phokoso lokhazikika komanso lomveka bwino pa workpiece. Izi ndizopindulitsa makamaka pamapulogalamu omwe amafunikira mawonekedwe apamwamba.

5. Kutuluka kwa chip ndi kuzizira bwino: Chophimba cha buluu cha nano chimapangitsa kuyenda kwa chip ndi kugawa koziziritsa, kuteteza kutsekeka kwa chip ndikuwonetsetsa kuti kutentha kwachepa. Izi zimathandiza kusunga ntchito yabwino yodula ndikuchepetsa chiopsezo cha kulephera kwa chida.

6. Kukana kwa dzimbiri: Chophimba cha buluu cha nano chimapereka chotchinga choteteza ku dzimbiri, kukulitsa kulimba kwa mphero ndikuchepetsa kuthekera kwa kulephera msanga chifukwa cha kuwonongeka kwa mankhwala.

7. Kusinthasintha pamakina opangira makina: Makina omaliza amtundu wa tungsten carbide square end okhala ndi zokutira za buluu za nano atha kugwiritsidwa ntchito pazinthu zosiyanasiyana, kuphatikiza zitsulo zosapanga dzimbiri, zitsulo zolimba, chitsulo chosungunuka, ndi zitsulo zopanda chitsulo. Iwo ndi oyenera roughing, kumaliza, ndi contouring ntchito, kupereka kusinthasintha Machining ntchito.

8. Kukhazikika kwa chida chowongolera: Chophimba cha buluu cha nano chimathandizira kuchepetsa kugwedezeka ndikuwongolera kukhazikika kwa chida panthawi yodula, zomwe zimapangitsa kudalirika kwapamwamba komanso kulondola kwazithunzi.

9. Zopindulitsa za chilengedwe: Kugwiritsa ntchito mphero yapamwamba kwambiri yokhala ndi nano buluu yokutira kungachepetse magawo ocheka, monga kudula mphamvu ndi kudula liwiro. Izi zitha kubweretsa kupulumutsa mphamvu ndikuchepetsa kugwiritsa ntchito zinthu, zomwe zimathandizira kuti makina obiriwira azikhala obiriwira komanso okhazikika.

| M'mimba mwake (mm) | Kutalika kwa tsamba (mm) | Zonse(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |