Solid Carbide roughing End Mill

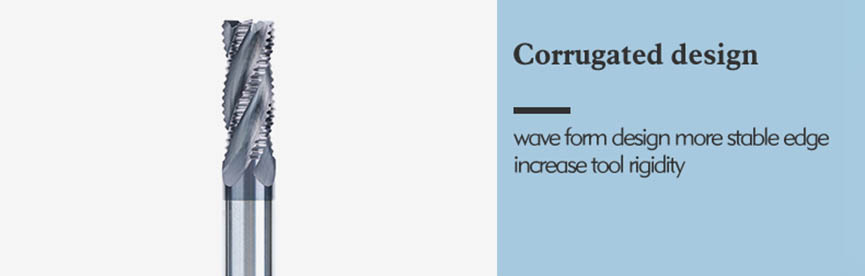

Mawonekedwe

1. Kuchulukirachulukira kochotsa zinthu: Makina opangira ma tungsten carbide amapangidwa ndi zitoliro zochepa poyerekeza ndi mphero zokhazikika. Izi zimalola kuti chip chichuluke komanso kuchitapo kanthu mwamphamvu kwambiri, zomwe zimapangitsa kuti pakhale mitengo yochotsa zinthu zambiri. Iwo ndi abwino kwa mwamsanga kuchotsa wambirimbiri zinthu mu roughing ntchito.

2. Kuuma kwakukulu ndi kukana kuvala: Tungsten carbide imadziwika ndi kuuma kwake kwapadera komanso kukana kuvala. Izi zimapangitsa mphero zomata zopangidwa kuchokera ku tungsten carbide kukhala zolimba kwambiri, ngakhale popanga zinthu zolimba monga chitsulo chosapanga dzimbiri, chitsulo cha aloyi, kapena chitsulo chonyezimira.

3. Mapangidwe a mano okhuthala: Mphero zokhotakhota nthawi zambiri zimakhala ndi mano akulu komanso odulira motalikirana poyerekeza ndi mphero zina. Kapangidwe kameneka kamathandizira kutulutsa bwino kwa chip ndikuletsa kutsekeka kwa chip, kuwonetsetsa kuti kudula bwino.

4. Ma chip breakers: Mphero zina za tungsten carbide zimatha kukhala ndi zopyola chip kapena zogawanitsa m'mphepete. Izi zimathandizira kuthyola tchipisi tating'onoting'ono, tinthu tating'onoting'ono, kulimbikitsa kuthamangitsidwa kwa chip ndikuchepetsa chiwopsezo cha kuwonongeka kwa zida zogwirira ntchito.

5. Kutentha kwakukulu kwa kutentha: Kutentha kwapamwamba kwa tungsten carbide kumalola kuti mphero zowawa zithe kupirira kutentha komwe kumapangidwa panthawi yochotsa zinthu zolemera. Kukana kutentha kumeneku kumathandizira kupewa kusinthika kwa zida kapena kulephera kwachida msanga, kuonetsetsa kuti chida chizikhala ndi moyo wautali.

6. Maonekedwe a helix kapena mamvekedwe osinthika: Mphero zina zokhotakhota zimakhala ndi mawonekedwe osinthika a helix kapena mamvekedwe osinthika pazitoliro zawo. Izi zimathandizira kuchepetsa macheza ndi kugwedezeka panthawi yodula, zomwe zimapangitsa kuti pamwamba pakhale bwino komanso kukhazikika kwa zida.

7. Zosankha zokutira: Mphero zowonongeka zimatha kuphimbidwa ndi zokutira zosiyanasiyana, monga TiAlN, TiCN, kapena AlTiN. Zopaka izi zimathandizira magwiridwe antchito a chipangizocho pochepetsa kugundana, kukulitsa kuyenda kwa chip, ndikuwongolera kukana kuvala. Kusankhidwa kwa zokutira koyenera kumadalira ntchito yeniyeni ndi zida zogwirira ntchito.

8. Ntchito yomanga molimba: Mphero za Tungsten carbide zimamangidwa molimba komanso zolimba kuti zipirire zovuta zomwe zimafunikira. Zapangidwa kuti zigwirizane ndi mphamvu zodula kwambiri komanso zimapereka bata panthawi yochotsa zinthu zolemera.

9. Zosankha za Shank: Mphero za Tungsten carbide roughing ends zilipo ndi zosankha zosiyanasiyana za shank, kuphatikizapo shank zowongoka, shanks za Weldon, kapena Morse taper shanks. Kusankhidwa kwa shank kumadalira chogwiritsira ntchito makina ndi zofunikira zenizeni za makina opangira makina.

10. Ma geometries a zida: Makina opangira mphero amatha kukhala ndi ma geometries apadera kuti akwaniritse ntchito yodula. Ma geometries awa atha kuphatikizira kuchuluka kwa mainchesi, ma radii olimbikitsidwa, kapena kukonzekera kwapadera kowonjezera mphamvu ndi magwiridwe antchito panthawi yovuta.

Chiwonetsero chatsatanetsatane

NDALAMA