Solid Carbide Square End Mills opangira makina wamba

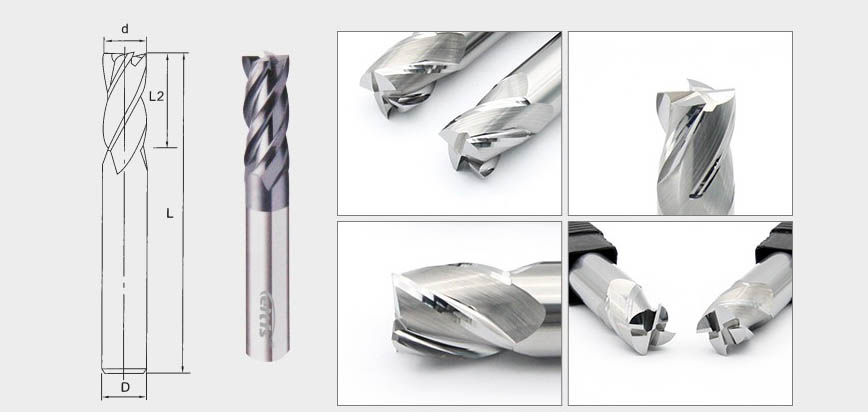

Mawonekedwe

1. Zofunika: Mapiritsi olimba a carbide square end mphero amapangidwa kuchokera ku chinthu chimodzi cha carbide, chomwe chimatsimikizira kukhazikika kwakukulu ndi kukana kuvala ndi kung'ambika.

2. Kuuma: Carbide imadziwika ndi kuuma kwake kwapadera. Ma mphero olimba a carbide square amatha kupirira kuthamanga kwambiri ndikusunga kuthwa kwawo kwanthawi yayitali poyerekeza ndi zida zina.

3. Kulondola: Makina olimba a carbide square end amapangidwa molunjika m'malingaliro. Amatha kupanga mabala olondola komanso aukhondo, zomwe zimapangitsa kuti zikhale zolondola komanso zapamwamba kwambiri.

4. Kusinthasintha: Makina omalizirawa amatha kugwiritsidwa ntchito muzinthu zosiyanasiyana, kuphatikizapo zitsulo zachitsulo ndi zopanda chitsulo, mapulasitiki, ndi ma composite. Kusinthasintha kumeneku kumawapangitsa kukhala oyenera kugwiritsa ntchito makina osiyanasiyana.

5. Kuchita bwino: Makina olimba a carbide square end amapangidwa ndi zitoliro zingapo, zomwe zimapangitsa kuti chip chisamuke ndikuchepetsa mwayi wotsekeka. Izi zimapangitsa kuti makina azigwira bwino ntchito komanso zokolola zonse.

6. Kutentha kwa kutentha: Carbide ili ndi zinthu zabwino kwambiri zotsutsana ndi kutentha, zomwe zimalola mphero zolimba za carbide square kuti zipirire kutentha komwe kumapangidwa panthawi yocheka popanda kutaya kuuma kapena kukhwima.

7. Moyo wautali: Chifukwa cha kuuma kwawo kwakukulu ndi kulimba, mphero zolimba za carbide square zimakhala ndi moyo wautali poyerekeza ndi mitundu ina ya mapeto. Izi zimabweretsa kuchepa kwa zida m'malo, kuchepetsa nthawi yotsika komanso mtengo.

8. Kusasunthika kwakukulu: Mphero zolimba za carbide zimakhala zolimba kwambiri, kutanthauza kuti sizimapindika kapena kupotoza panthawi ya makina. Kusasunthika kumeneku kumabweretsa kukhazikika kodula komanso kulondola kwazithunzi.

9. Zosankha zokutira: Makina opangira ma carbide square end mphero amathanso kuphimbidwa ndi zokutira zosiyanasiyana monga TiN, TiCN, ndi TiAlN, zomwe zimawonjezera magwiridwe antchito awo pochepetsa kukangana, kukulitsa moyo wa zida, komanso kukonza kutulutsa kwa chip.

10. Cutting-edge geometry: Makina olimba a carbide square end mphero amapezeka mumitundu yosiyanasiyana yamitundu yosiyanasiyana, monga mawonekedwe owongoka, a helical, ndi ma helix osiyanasiyana. Ma geometries awa amapereka mawonekedwe osiyanasiyana odulira komanso amakwaniritsa zofunikira za makina.

Chiwonetsero chatsatanetsatane

NDALAMA

Ubwino wake

1. Kukhalitsa: Makina olimba a carbide square ends amadziwika ndi kukhazikika kwawo kwapadera. Zinthu za Carbide sizimva kuvala ndipo zimatha kupirira kuthamanga kwambiri komanso zida zowononga, zomwe zimapangitsa moyo wautali wa zida.

2. High Speed Machining: Makina olimba a carbide square end mphero amatha kuchita bwino kwambiri machining othamanga kwambiri chifukwa cha kuuma kwawo komanso kukana kutentha. Izi zimapangitsa kuti ntchito ziwonjezeke komanso nthawi yayitali yamakina.

3. Kuthamangitsidwa Kwabwino Kwambiri kwa Chip: Zitoliro pazitsulo zolimba za carbide square end mphero zidapangidwa kuti zithandizire kuthamangitsidwa kwa chip. Izi zimathandiza kupewa chip build-up ndikuonetsetsa kudula kosalala, kuchepetsa chiopsezo cha kuwonongeka kwa zida kapena kuwonongeka kwa workpiece.

4. Pamapeto Pamwamba Pamwamba: Makina olimba a carbide square end amatulutsa mabala oyera komanso olondola, zomwe zimapangitsa kuti pakhale kutsirizika kwapamwamba pa workpiece. Izi zimathetsa kufunikira kwa njira zowonjezera zomaliza, kupulumutsa nthawi ndi mtengo.

5. Kusinthasintha: Mitsulo yolimba ya carbide square end ndi yoyenera kuzinthu zosiyanasiyana, kuphatikizapo zitsulo, mapulasitiki, ndi ma composites. Kusinthasintha kumeneku kumawapangitsa kukhala abwino m'mafakitale osiyanasiyana, kuyambira zamagalimoto mpaka zakuthambo.

6. Kukhazikika Kwambiri: Makina olimba a carbide square end mphero amakhala ndi kukhazikika kwakukulu, zomwe zimachepetsa kupotoza kwa zida ndikuwonjezera kukhazikika kwa kudula. Izi zimabweretsa kulondola kwazithunzi komanso kuchepetsa mwayi wosweka kwa zida.

7. Precision Machining: Mphepete zakuthwa za mphero zolimba za carbide square end zimalola makina olondola komanso olondola. Izi ndizofunikira kwambiri pamapulogalamu omwe amafunikira kulolerana kolimba komanso tsatanetsatane watsatanetsatane.

8. Kulimbana ndi Kutentha: Miyendo yolimba ya carbide imatha kupirira kutentha kwambiri komwe kumapangidwa panthawi yopangira makina. Kukana kutentha kumeneku kumalepheretsa chidacho kuti chifewetse kapena kutaya katundu wake wodula, kuonetsetsa kuti ntchito yokhazikika.

9. Kusintha kwa Zida Zochepetsera: Makina olimba a carbide square end mphero amakhala ndi moyo wautali wa zida poyerekeza ndi zida zina, kuchepetsa kufunika kosintha zida pafupipafupi. Izi zimabweretsa kuwonjezeka kwa kupanga komanso kuchepa kwa nthawi.

10. Mtengo Wogwira Ntchito: Ngakhale poyamba okwera mtengo, mphero zolimba za carbide square end mphero zimapereka ndalama zochepetsera nthawi yayitali chifukwa cha moyo wawo wautali wa zida ndi luso lapamwamba. Izi zimawapangitsa kukhala kusankha kotsika mtengo kwa ntchito zopanga.

| M'mimba mwake (mm) | Kutalika kwa tsamba (mm) | Zonse(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |