Tungsten Carbide roughing End Mill

Mawonekedwe

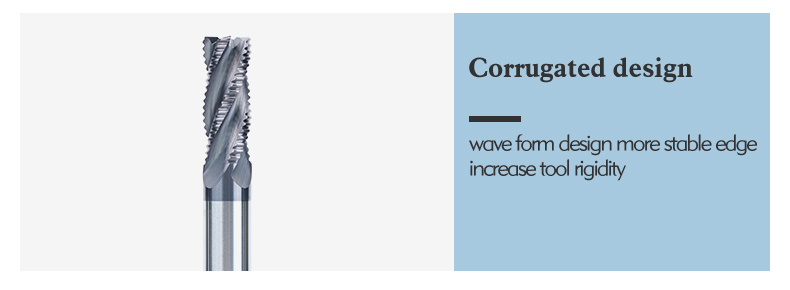

Carbide roughing end mphero ali ndi zinthu zingapo zodziwika:

1. Mapeto otsirizawa amapangidwa kuti achotse bwino zinthu panthawi ya roughing, kuwapanga kukhala oyenera makina othamanga kwambiri komanso kuchotsa zinthu zolemetsa.

2. Zopangidwa ndi tungsten carbide yapamwamba kwambiri, mphero zotsirizirazi zimapereka kuuma kwapamwamba komanso kulimba kuti zipirire zovuta zakugwiritsa ntchito movutikira.

3. Mphero zokhotakhota zimakhala ndi mapangidwe olimba omwe amathandizira kudula mwamphamvu ndikuchotsa chip, zomwe zimapangitsa kuti zinthu zichotsedwe mwachangu.

4. Oyenera kupanga makina ovuta a zipangizo zosiyanasiyana, kuphatikizapo zitsulo, zitsulo zosapanga dzimbiri, zitsulo zotayidwa ndi zitsulo zina zachitsulo komanso zopanda chitsulo.

5. Makina omaliza amapangidwa kuti azitha kupirira kutentha kwambiri komwe kumachitika panthawi yamavuto, kuchepetsa kutentha kwa kutentha ndikuwonetsetsa kuti nthawi yayitali ya zida.

6. Mphero zina zomangika zimatha kukhala ndi zokutira zapadera monga TiCN (titanium carbonitride) kapena AlTiN (aluminium titanium nitride) kuti awonjezere kukana komanso kukulitsa kugwiritsa ntchito kwa chida pansi pamikhalidwe yovuta. moyo.

7. Mapeto otsiriza amapangidwa kuti apereke bata ndi kukhazikika panthawi yodula mwaukali, kuchepetsa kugwedezeka ndi kuonetsetsa kuti ntchitoyo ikugwira ntchito mosasinthasintha.

8. Konzani kamangidwe ka chip chochotsa poyambira ndi geometry ya chip breaker, yomwe imathandizira kuchotsa chip, imalepheretsa kudulidwanso kwa chip, ndikuwongolera magwiridwe antchito.

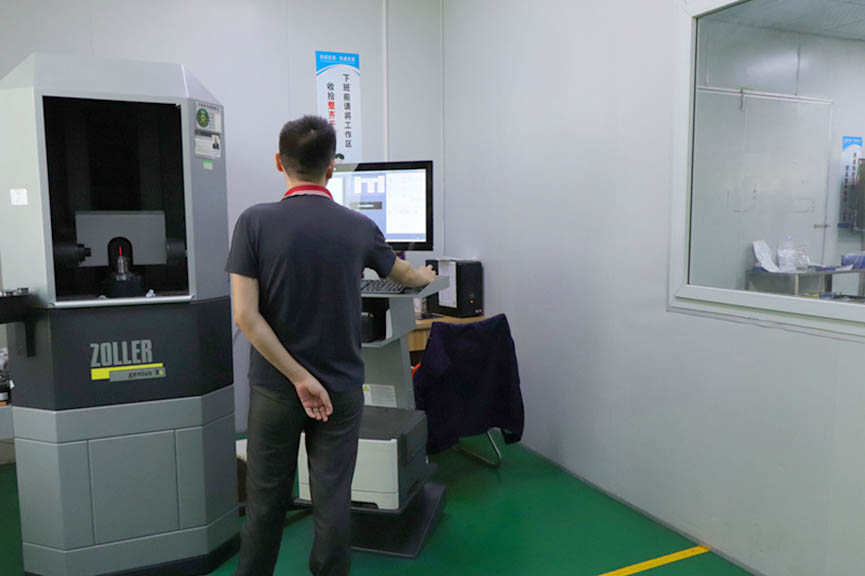

PRODUCT SHOW